Drion·tec® D-Spade D5142

Double Cutting Edge – Double Tool Life!

Are you looking to reduce your tool costs, e.g. in mass or series production, while achieving maximum performance and optimum drilling quality, e.g. in terms of surface quality, tolerances and straightness? Then the Drion·tec® D-Spade exchangeable-tip drill D5142 is the perfect solution for you! As a series manufacturer of steel or cast iron components, you can now double your performance with the D5142 without compromising on quality.

The Drion·tec® D-Spade D5142 is the world's first indexable drill with a double-sided exchangeable tip, i.e. with 2 usable cutting edges. This drill is unique on the market! Not only does it double tool life, unlike tools with replaceable heads, for example, it also completely redefines the relationship between price and tool life because the exchangeable tip can simply be turned over. Go to the video

»With this new system, the customer saves over 45% of its cutting tool costs per year!«

|

| Stefan Wickles, Walter Application Engineer |

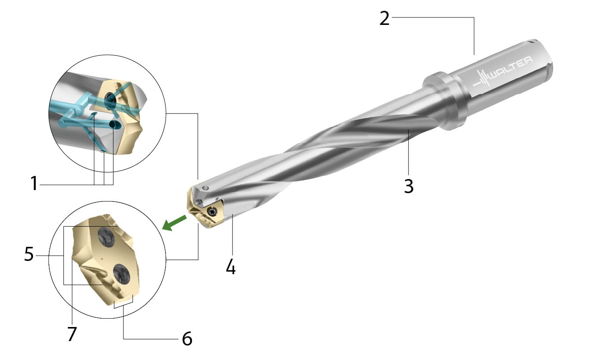

(1) Precision cooling: 6 coolant outflows – on main cutting edge, cross cutting edge and circumference

(2) Cylindrical shank with parallel flat according to ISO 9766

(3) Ground and polished chip flutes

(4) Drion·tec® D-Spade design – patent pending

(5) Two cutting edges

(6) 4 straight margins on the circumference

(7) Self-centring tip grinding

The symmetrical Drion·tec® D-Spade design with 2 cutting edges per exchangeable tip is completely new on the market: The flank face of the first cutting edge forms the contact surface for the second cutting edge. Two radial screws clamp the exchangeable tip securely in place.

- Ultra-cost-efficient thanks to double exchangeable tip tool life due to symmetrical design with two cutting edges per tip

- Outstanding bore quality thanks to 4 margins and self-centering point geometry

- Maximum process reliability thanks to ground and polished chip flutes and 6 coolant outflows for precise cooling

- Sustainable thanks to 45% less carbide per cutting edge (compared to standard solutions)

- Wear-resistant with easy wear detection thanks to fine-grained substrate with HiPIMS coating and gold-colored top layer

»Contrary to initial concerns, both cutting edges had the same tool life!«

|

| Walter Customer |